Spring Ring Clasps: All You Need to Know

Learn everything you need to about spring ring clasps to help you make an informed decision. This post covers the construction, the benefits, and tips for the proper care and usage.

Spring rings are one of the most common types of clasps used in jewelry making. You’ll find them on everything from chains to beaded designs to pendants strung on cord or silk. How do you know if it’s the right clasp for your design? We’ll go through the ins and outs of a spring ring, discussing how they’re made, the benefits, and proper usage and care so you can get the most out of your clasp.

Spring Ring Construction

First up – construction! To know if a spring ring is the right option, first, we must understand how they’re made. This includes the parts to a whole, assay considerations, and plating and after-market treatments.

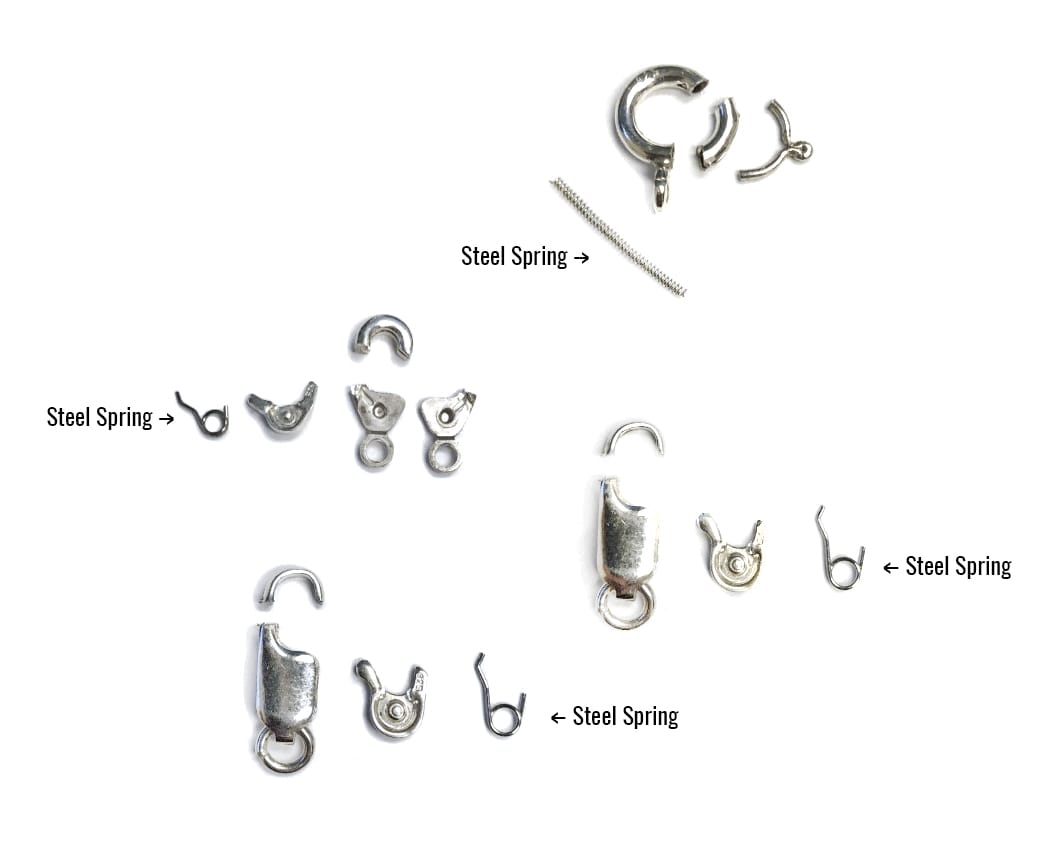

Construction of a Spring Ring

Spring rings include three components – the tube, the spring, and the trigger. The spring and trigger are loaded into a hollow tube and when you pull the trigger, it compresses the spring – opening the clasp! Pretty straightforward once you can see the insides. When the clasp closes, the trigger slides into the tube, ensuring a secure closure.

The Magnet Test

Spring ring hollow tubing and trigger wires are made from the primary material metal; usually sterling silver, 14k gold, or gold-filled. However, the coiled spring is always made out of steel. You will notice in the deconstructed spring ring photos that the spring is a darker metallic material. This is because a precious metal spring would quickly lose its tensile strength with repeated use and would stop functioning. Steel springs maintain this important tensile strength “springy” property for lifetime use. The Federal Trade Commission (FTC) regulates jewelry industry practices. They allow certain key jewelry components to contain steel mechanisms because of the necessity for tensile strength. These components include clasp springs, hinge pins in items like leverback earring findings, and the glass-face holding bezels for lockets or watches. These particular findings may be magnetic because of the small steel components even though the main body of these items is made from precious metal. You may notice a stronger magnetic pull on the findings when you are near the steel mechanism component.

Assay

The introduction of steel into a clasp will affect the piece’s assay. What’s assay? Assay is a lab test used to determine the compositional breakdown of your piece to verify precious metal purity. For example, sterling silver is 92.5% fine silver, and 7.5% copper. With the addition of the steel spring, we’ve increased the weight of the piece with a new material, thus decreasing its purity. BUT, we want that steel spring in there because silver and gold don’t have the strength to act as springs, as mentioned above. The effect on assay is just something to keep in the back of your mind when using a spring ring, or any clasp that uses a steel spring – like a lobster clasp. If you are ordering quality control lab tests on your materials, you should always either remove clasps that contain steel springs or notify your lab tech that your testing sample may include clasp springs that should be taken out before analysis.

Plating and Treatments

Most spring rings are flash plated. That means they get plated in the finishing phase of manufacturing to make them clean and shiny. For many chain and findings items, it is more efficient to flash plate to achieve a bright finish instead of polishing or tumbling. Often, they’re also treated with an anti-tarnish solution that helps slow down the normal silver tarnishing process. This ensures your clasp looks good for a long time.

Priming Your Spring Rings – IMPORTANT!

Because of plating and anti-tarnish treatments, your first few uses of a spring ring trigger can be a little sticky – you may have to break through the plating and anti-tarnish surface treatments to loosen the trigger action. Don’t be concerned, this is normal for spring rings and is part of the economy experience, and why they are so affordable. However, once you have used the clasp a few times, the movement will be nice and smooth. If you notice the trigger isn’t working properly, we recommend opening and closing the spring ring about 4-6 times to clear the tubing of any obstructions from the manufacturing process. You’re going to want to keep this concept in mind if you add any coatings or patinas as well. Anything can get into that mechanism and gum it up. If it’s something you are especially concerned about, consider a switch to lobster clasps.

Spring Ring Clasp Benefits

Now that we’ve got some of the technical stuff covered – let’s talk about why we love spring rings! There are two big things that make these little clasps so popular. They’re affordable and come in different sizes and material varieties.

Affordability

As makers, we always keep the cost of materials in mind because that affects the final retail price. Spring rings are a great clasp option because they are often the least expensive. Because they’re hollow, they’re lightweight and use less material than say, a lobster clasp. We mentioned lobster clasps earlier because they also have an interior spring. However, they are constructed differently. The body of a lobster clasp is not a round tube, thus making it a bit heavier, and more expensive. We’ll touch on why you might want a heavier clasp in the Care and Usage section of this post. Overall though, spring rings will always be cheaper and lighter than lobster clasps and can be the perfect ending to a delicate chain.

Variety

Spring rings are also great options because they come in a variety of sizes and materials. Here at Halstead, we carry them from 5.5mm to 8mm in sterling silver and 5.5-9.5mm in gold-filled. Variation in size is useful because it means you can use them in different applications, from smaller chains to larger chains and beyond. Don’t forget to consider the weight in relation to the chain and pendant when selecting the right size clasp for your piece. Heavier clasps tend to swing to the front of your necklace. To combat this, you may choose to intentionally use a larger, more ornate clasp and make it a design decision!

You also want to consider the size of the clasp in relation to its function – the smaller the spring ring, the less clearance there is for the spring to move, thus you have a smaller opening. With lobster clasps, there are fewer limitations. Additionally, because spring rings are such a popular option, it means you can find them in a variety of different materials. Silver, gold-filled, gold – you name it! This ensures you can always match your clasp material to your needs.

Care and Usage

Ok, awesome – we’ve covered why spring rings are so great and now that we’ve decided to use one, let’s talk care and usage. You may choose to solder your spring ring to your chain, and you want to make sure to keep a few things in mind when doing so. I’ll cover tips and tricks for soldering near a spring ring to avoid any mishaps. I’ll also cover concerns over durability, longevity, and ease of use.

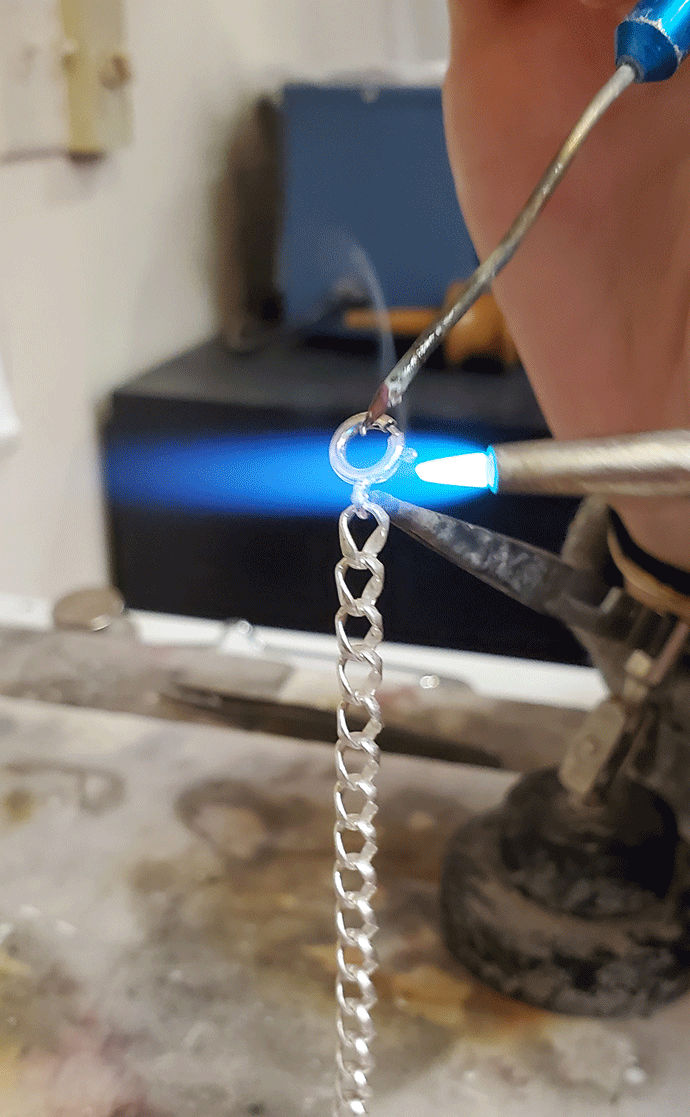

Soldering Near Spring Rings

I first want to cover connecting your clasp to your chain. This can be done with a jump ring or the ring that is attached to the clasp. Because of this, you might want to solder it closed for extra security. This IS possible, but you want to be extra careful while doing so! The addition of heat (about 250-500 degrees F) near or on the clasp can cause the spring to lose its springy-ness, and that’s obviously bad. See some tips below for soldering a spring ring to chain.

- Use the smallest flame needed to get the job done, and easy-flow solder! – smaller flame + lower melting temperature = less heat

- Hold your piece in cross-locking tweezers – Place the tweezers between the clasp and the flame as best you can. This acts as a heat sink, helping prevent the transfer of heat into the spring.

- Quick pickle – Make sure your clasp is only in the pickle long enough to remove oxidation and flux. Any longer and the steel will react with the acid and can cause copper plating.

- Rinse thoroughly! – Because spring rings are hollow, you want to make sure all the pickle is out of the tube. If not, it can slowly leak out and get all crusty – yuck!

- If needed, after pickling, gently heat a tiny drop of beeswax into the spring to help lubricate it.

Using a Spring Ring

Spring rings can be a long-lasting and durable clasp option – if you treat them with care. Only apply the amount of pressure you need. Spring rings can be delicate and if you really jam on the trigger, you will wear the spring out faster. It is only necessary to open a small gap to accommodate your attachment jump ring. You don’t need to yank the trigger all the way back.

Generally speaking, spring rings are more delicate than lobster clasps. As mentioned, lobster clasps are constructed differently even though they both have an internal spring. Because a lobster clasp does not utilize a hollow tube, it’s more substantial and durable. This can be a factor in longevity, as well as use.

Spring rings can be difficult for some people to use, especially the smaller ones. You should consider this in relation to your customer audience. Clients who have reduced fine motor dexterity will be frustrated by spring rings. It’s a great idea to offer clasp upgrades to lobster claws or magnet clasps for an additional charge. This keeps your base price point low but allows customizations that customers value. With more body behind them, lobster clasps give you a little bit more to hold on to. Magnet clasps are a premium option for those who struggle with other clasps. They snap right into place, even when putting on your jewelry one-handed.

Wow, I know that’s a lot of information on something so tiny! Even the smallest parts of our jewelry require the utmost consideration. Spring rings are no exception! Now that you’ve got all the info laid out – construction, benefits, usage and care, and things to keep in mind – you can make the best clasp selection for your next jewelry project.

Source: Halstead