Why Platinum is Responsible

What Does Responsible Platinum Mean?

Responsible Platinum refers to the manner in which platinum is sourced, abiding by set guidelines to assure the metal is mined and produced meeting international ethical and environmental standards.

Industry-Leading ESG Standards

The majority of the platinum used to make jewelry is produced according to robust Environmental, Social and Governance (ESG) standards.

Platinum is very rare. Of the ~6 million troy ounces of platinum mined every year, over 80% is produced in South Africa, Zimbabwe and North America, following strict ESG guidelines concerning environmental standards, social impact and governance guidelines that include those mandating against the financing of conflict.

Platinum’s Non-Jewelry Benefits

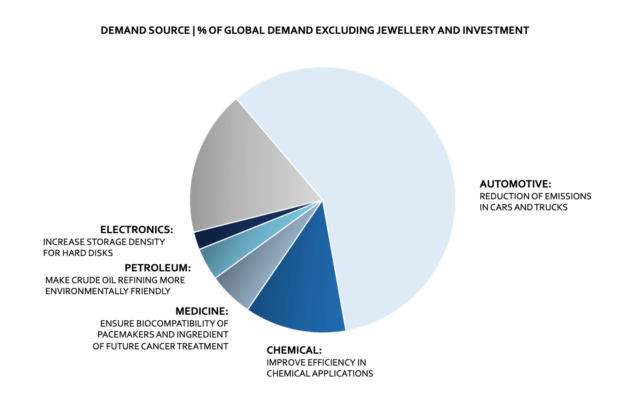

Over 80% of platinum’s non-jewelry usage benefits society: either in reducing emissions or improving health.

Platinum is central to reducing vehicle emissions both now and in the long term. Platinum is a key ingredient of diesel catalysts, and its superior catalytic and conductive properties can be used in hydrogen fuel cells to power electric cars with zero emissions.

Platinum catalysts increase yields in chemical processes, an example being more high-octane fuel per barrel of oil.

Because of its resistance to corrosion and lack of reactivity, platinum is biocompatible and used in pacemakers and other medical instruments placed in the body. Platinum-based therapies have been at the forefront of cancer treatment for more than forty years.

Even as an investment vehicle, platinum is indirectly supporting sustainable causes, e.g. through investments in start-ups working on fuel cell and hydrogen applications.

Platinum produced for jewelry is certified to be responsibly sourced, adhering to the ‘Good Delivery Practice’ standards of the London Platinum and Palladium Market (LPPM).

Source: Metals Focus

Good Delivery Practice

Conforming to the LPPM Responsible Sourcing Guidance is a requirement for all refiners wishing to achieve and maintain trading accreditation. This is intended to assure investors and consumers that all LPPM Good Delivery metal is conflict-free due to compliance with an audited sourcing process.

The Responsible Platinum and Palladium Guidance (RPP) is based on the OECD Due Diligence Guidance and Anti-Money Laundering and Combatting Terrorist Financing regulations.

RPP was introduced in 2019 and is aligned with the existing LBMA Responsible Sourcing Guidance documents. Platinum and Palladium good delivery refiners are required to comply with this new guidance in full from 2020 onwards.

To maintain inclusion on the LPPM’s Good Delivery Lists, refiners must pass an LPPM Responsible Sourcing audit every year and a Proactive Monitoring (PAM) every three years.

Supporting South Africa

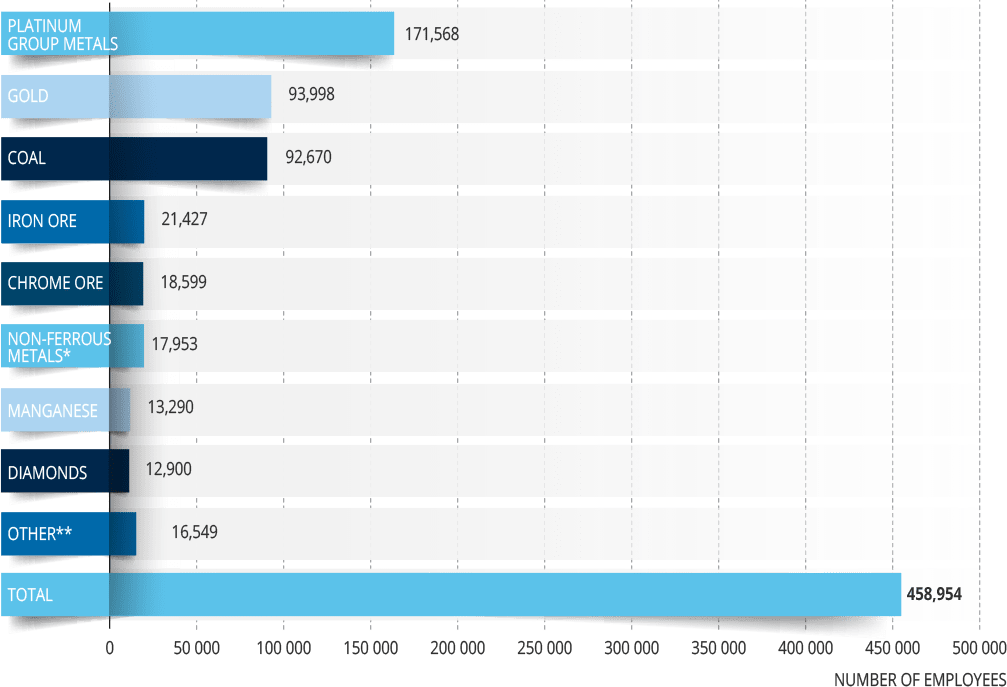

Platinum group metals (PGMs) mining is a significant job creator in South Africa, and the industry directly employed over 170k people in 2021– by far the most in the mining industry and a third of all miners employed across all commodities. PGMs industry contributes significantly towards the South African economy through revenue generation and tax payments into the fiscal budgets that fund social programs.

Platinum mining employs 170,000+ people in South Africa, more than any other commodity in the country. Every person employed in platinum mining is estimated to support another 7-10 people, making the overall impact on communities even bigger.

Note: 2021 data.

Source: Department of Mineral Resources and Energy, South Africa.

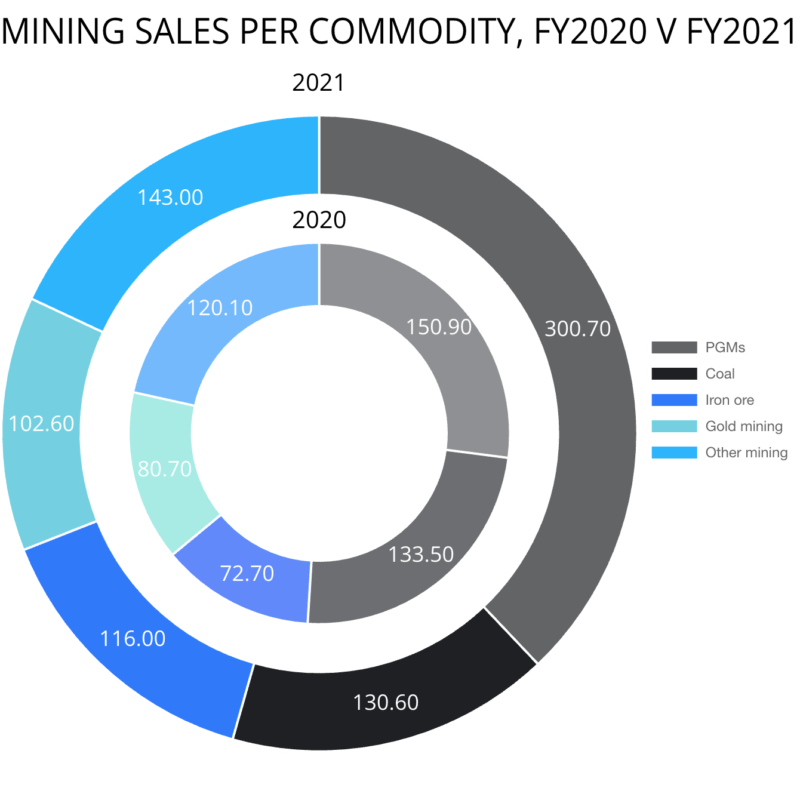

One of South Africa’s largest mining sub-sectors is PGMs, with the country being home to more than 50% of the world’s platinum reserves. The South African mining industry contributes meaningful economic and fiscal value through its operations, with PGMs contributing the largest portion to the total.

Note: Billion Rand.

Source: Stats SA, PwC analysis

Platinum in the Hydrogen Economy

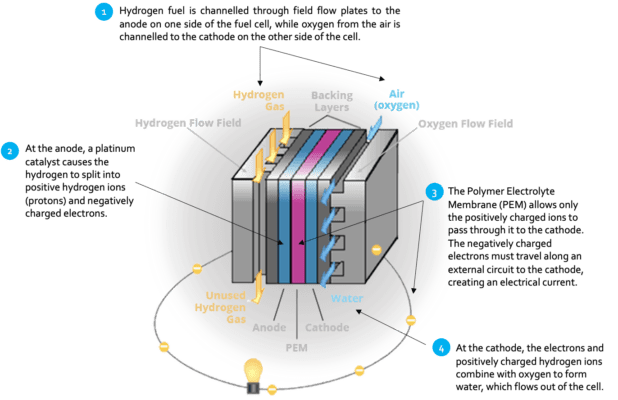

Platinum is a key component of the hydrogen economy, which has the potential to provide zero-emission energy storage solutions and zero-emission vehicles that all contribute to combatting climate change.

Due to its unique chemical and physical properties, platinum is at the forefront of proton exchange membrane (PEM) applications – transformative technology that holds the key to unlocking the zero-emissions potential of hydrogen. PEM technology is used in both electrolyzers to produce hydrogen and in hydrogen fuel cells which can power, for example, an emissions-free fuel cell electric vehicle (FCEV).

Hydrogen – the most abundant element on earth – is already used as a fuel source in certain industries. As it contains no carbon, it produces zero emissions – only water.

However, its credentials as a truly sustainable fuel source rest on the way in which it is produced. Green hydrogen is completely carbon-free as its production does not involve the use of any fossil fuels.

Source: fueleconomy.gov

Recyclable Platinum

Platinum is recyclable and has a mature and established recycling value chain.

The high and repeatable recyclability of platinum means that the environmental burden of platinum production decreases with each recycling round. Due to its lower environmental impact, secondary production plays an important role in lowering the environmental footprint of global platinum production.

In the context of the platinum life cycle, it must be understood that recycling could not occur if there had not been a primary ounce of platinum produced beforehand. Hence, there is industry-wide consent that secondary production is complementary to primary supply; ensuring the steady supply of platinum to meet society’s current and future needs requires both increased levels of recycling and ongoing investments in primary production.

Source: Platinum Guild International