Why Many Lab-Grown Diamonds Are Not Sustainable

WHY MANY LABORATORY-GROWN DIAMONDS ARE NOT SUSTAINABLE: FACTCHECK:

Laboratory-grown diamonds may not always be as sustainable as some claim. The manufacturing process, which lasts a few weeks, is energy- intensive, requiring temperatures similar to 20% of that of the Sun’s surfac. Over 60% of laboratory- grown diamonds are mass-produced in China and India where 63% and 74% of grid electricity is generated from coal.

Publicly available research reveals that the claim that laboratory-grown diamonds always have a low, neutral or even negative carbon footprint is not true. The environmental sustainability of laboratory-grown diamonds depends on the energy, chemical, material, water and waste management of the factory in which they are produced. It is also not possible to make a simplistic general comparison between natural diamonds and laboratory-grown diamonds. Each category has a range of production processes, geographical locations, power sources, productivity capabilities, and sustainability practices.

It is also a misconception that laboratory-grown diamonds are mining-free, as stated in some marketing campaigns. Synthetic diamond processes can require graphite and metals, and the reactors in which laboratory-grown diamonds are created are built with metals that all originate from mining.

Sustainability claims about laboratory-grown diamonds should be supported by evidence on their social footprint too, especially in areas relating to tax payments, employment and human rights, as well as the support provided for local communities in laboratory-grown diamond regions.

This chapter focuses largely on environmental sustainability and seeks to address these misconceptions with publicly available data.

Background on scale and emissions footprint of laboratory-grown diamonds

The energy required to grow laboratory-grown diamonds depends on many factors including the size of the diamond and the type and age of the machinery used. For example, large stones require more energy to be manufactured. The most significant factor that impacts energy usage is the method used (HPHT or CVD) in their manufacturing. The emissions generated by laboratory-grown diamond manufactures depend on the amount of energy required and the energy source used. If electricity is sourced is sourced from the national grid, it will depend on the geographical location too.

In 2021, the majority of laboratory-grown diamonds were produced in China (41%) and India (20%), both of which have a heavy dependence on coal for electricity production. The $22 billion global laboratory-grown diamond industry is growing quickly. At the end of 2022, expert industry analyst Paul Zimnisky noted that the output of the laboratory-grown diamond industry has reached between 7-9 million carats. The industry’s production capacity stood at around 6-7 million carats in 2020, indicating that production capacity is increasing.

The energy consumption of laboratory-grown diamonds

The energy mix where laboratory-grown diamonds are produced is important when considering how sustainable they are because the production of laboratory-grown diamonds is highly energy- intensive. As previously stated, there are two main methods of producing laboratory-grown diamonds: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). The latter is significantly more energy intensive, mainly due to the use of plasma microwaves that require very high power.

In these processes, energy is required for extreme heating, up to around 1,500 degrees°C and for HPHT for high-pressure conditions. A considerable amount of water is also required in some factories for cooling systems for reactors. Energy is also needed to stabilize the environment within the factory to ensure external conditions do not impact the growth of the synthetic diamond.

If electricity used in the production phases of laboratory-grown diamonds originates from non-renewable sources, this can contribute to laboratory-grown diamonds’ GHG emissions.

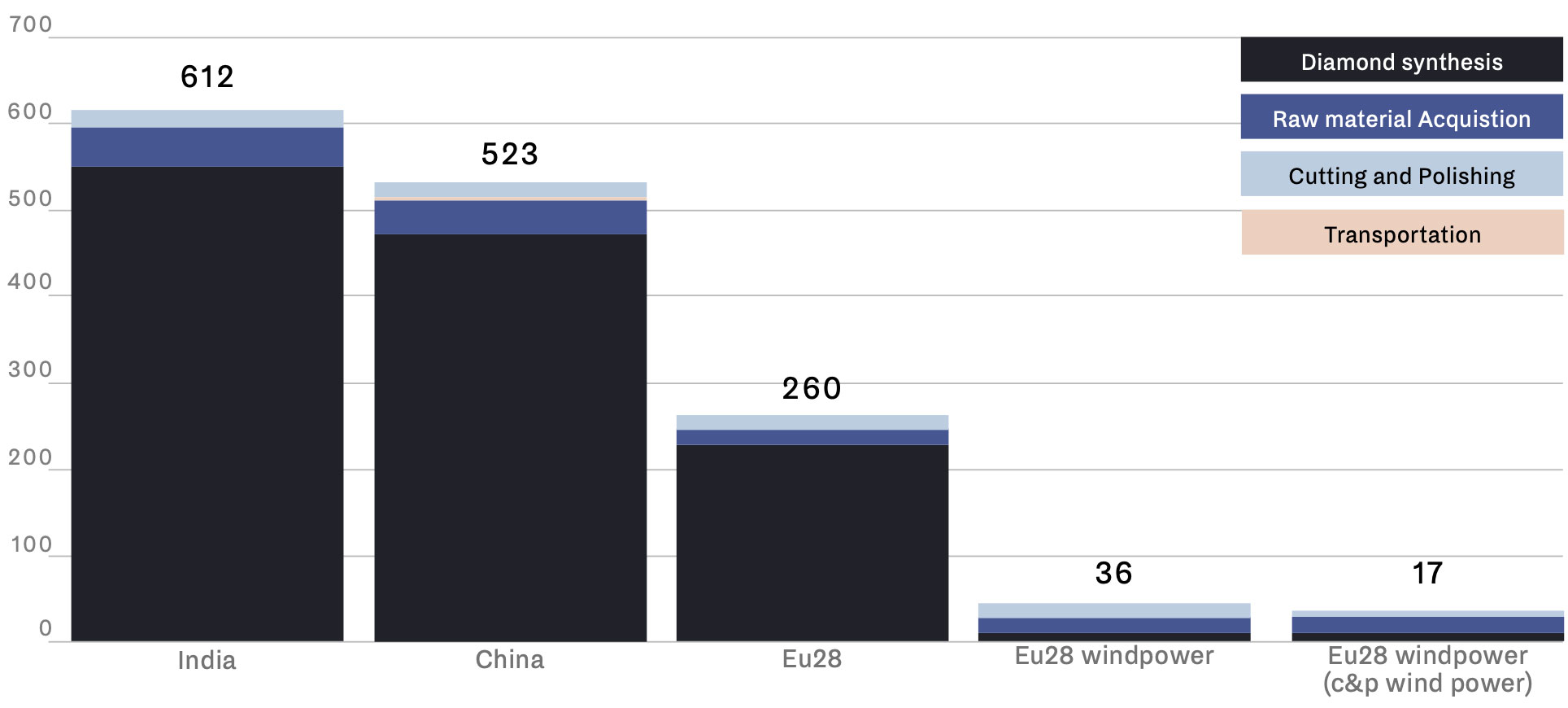

So, what is the exact carbon footprint of a laboratory-grown diamond? Few laboratory-grown diamond companies transparently disclose or verify such data and the truth is, there is no single agreed upon figure. It is dependent on multiple factors including the method of production, the region and the methodology used to calculate the footprint. Sphera have estimated that the average emissions per polished carat produced by the CVD process can vary from 260kg C02e to 612kg CO2e in India. In the instance that 100% renewable energy is used then their research estimates this figure can be as low as 17kg CO2eq per polished carat of laboratory-grown diamond.

CHEMICAL VAPOR DEPOSITION: EXPLAINED

The CVD diamond growth process involves placing seed crystals in a chamber that is filled with gas and heated to temperatures of 900- 1200°C. A microwave beam causes carbon to form out of a plasma cloud which is then deposited onto the crystal to form a diamond. The entire process usually takes 3 weeks to a month before they are ready to be cut and polished.

CARBON INTENSITY: EXPLAINED

HPHT involves placing a diamond seed into a capsule which is placed into a press. The capsule is heated to temperatures of 1300- 1600 °C with pressures above 870,000 pounds per square inch. According to the GIA, this pressure is roughly equivalent to the pressure exerted by a commercial jet airplane if balanced on the tip of a person’s finger. Metal in the growth capsule melts and dissolves the high purity carbon source and carbon atoms are then deposited on the seed crystal to generate diamond growth. Following conversations with industry professionals, we learnt that each HPHT reactor can weigh around 50 tonnes.

The carbon footprint of a 1 carat cut and polished laboratory-grown diamond

Within the laboratory-grown diamond market, different producers use different reactors in their production processes, which have varying energy efficiencies. This further impacts the accuracy of generalized figures that are often used. Just as some natural diamond companies use renewable energy, there are instances where laboratory-grown diamonds use renewable sources for their processes. Hydropower is a reliable renewable source and it can provide a constant source of the high-intensity energy that is required for the growing process of a synthetic diamond. In these instances, it is fair to say that these laboratory-grown diamonds are more environmentally sustainable than orthodox mass-produced laboratory-grown diamonds where factories and machinery rely heavily on fossil fuels and non- renewable sources.

To navigate these complexities and if it is of interest, buyers should ask for carbon footprint data from the specific laboratory-grown diamond factory that produced their diamond. There is limited data and transparency about carbon emissions from laboratory-grown diamonds. The International Grown Diamond Association plans to work with its members to address the lack of disclosure about their environmental impact.

The carbon footprint of a one carat cut and polished laboratory-grown diamond. Source: Sphera

Also, claims that laboratory-grown diamonds always have a lower carbon footprint and are therefore always more sustainable than natural diamonds are not true. The answer is dependent on numerous variables, especially in the natural diamond recovery process. These include geography, the productivity of the mine and the use of renewable energy.

There is a common misconception that laboratory-grown diamonds are always mining-free. This is not entirely true. Laboratory-grown diamond synthesis requires the production of machines to carry out various processes. Machinery and machine processes involved at laboratory-grown diamond factories, like the presses, are made of high-grade steel, a material that has a high level of embodied carbon. Additionally, manufacturing HPHT synthetic diamonds requires graphite, metals like nickel, iron and cobalt and pyrophylite – albeit in small quantities. Equally, synthetic diamonds produced via CVD require methane and hydrogen. Methane is generally sourced from the mining of fossil fuels like gas, oil and coal.

On water usage, some HPHT factories require the use of large volumes of water to cool their equipment and maintain the humidity levels needed to grow laboratory-grown diamonds.

In China, where the majority of HPHT production takes place, factories use common water reservoirs to cool the HPHT presses and this reservoir water can be used multiple times. Research has found that in general, water consumption for the HPHT and CVD methods is materially insignificant, approximately 0 and 0.002 m3 per carat, respectively. When it comes to exact figures on water recycling, there is little publicly available data on this to review.

A note on greenwashing

The global crackdown on greenwashing, specifically on misleading environmental claims, has addressed the sustainability statements made by certain producers of laboratory-grown diamonds.

The Federal Trade Commission in the US sent warning letters to companies in 2019 regarding their diamond advertisement disclosures. It noted that any campaigns that claimed products were ‘eco-friendly’, ‘eco-conscious’, or ‘sustainable’ without specific evidence or data to back this up would be placed under review.

It also started a public consultation process with the purpose to review its Green Guides. The UK’s Competition and Markets Authority (CMA) published its Green Claims Code52 and France has brought in fines against companies found to be greenwashing.

The European Union has also announced a set of new legislations aimed at tackling eco-claims. This underscores the importance of ensuring that any sustainability claims made by producers of laboratory-grown diamonds can be sustained and are underpinned by robust evidence.

What about laboratory-grown diamonds’ social sustainability performance?

Any broad claims that laboratory-grown diamonds are always a sustainable option must consider the social implications of the industry across the entire supply chain too.

Whilst this chapter has focused a lot on environmental sustainability, social conditions relating to employment and human rights, as well as the impact and mediation with local communities in laboratory-grown diamond regions, are fundamental to ensuring that when it comes to water usage, laboratory-grown diamonds can justify their ethical sourcing claims.

There is less access to published data and information about the social footprint of laboratory-grown diamond manufacturers and they are not held to account on reporting guidelines.

Additionally, as laboratory-grown diamond production has a business model that relies on technology-based manufacturing, the number of employees it must hire for direct production is significantly smaller than that of the natural diamond industry. There is also much less local procurement and incomparably less infrastructure and social investments made or partnerships developed with local communities.

This means that that laboratory-grown diamonds do not have t have the same socio- economic benefits for communities or positive social multiplier effect as natural diamonds have. The natural diamond industry operates largely in developing countries, so contributes to the important economic development of producer countries.

Source: Natural Diamond Council