Bench Jeweler’s Guide to Moissanite

Setting: Moissanite is a tough material with a hardness of 9.25 on the Mohs scale. It is not easily prone to damage, but chipping may occur if special care is not given where sharp points and thin girdles are concerned. For instance, the sharp points on the radiant, princess, square brilliant, pear, etc., must be protected against unnecessary pressure. Small indentations should be drilled where the points of the stone will rest. This will allow setting pressure against the sides but will avoid pressure against the points.

Trimming Metal Prongs: Only rubber wheels should be used around the prongs. Do not use stone, silicon carbide (carborundum), or diamond abrasives as these types of wheels will scratch the moissanite. If using files to trim the prongs, avoid passing the file over the sharp facet edges or the girdle edges as this can chip the moissanite but not scratch it. One way to avoid the rough file catching on the stone’s edge is to use a three-corner file, and then grind down and polish the corners. Emery paper and buff sticks are best suited for trimming prongs.

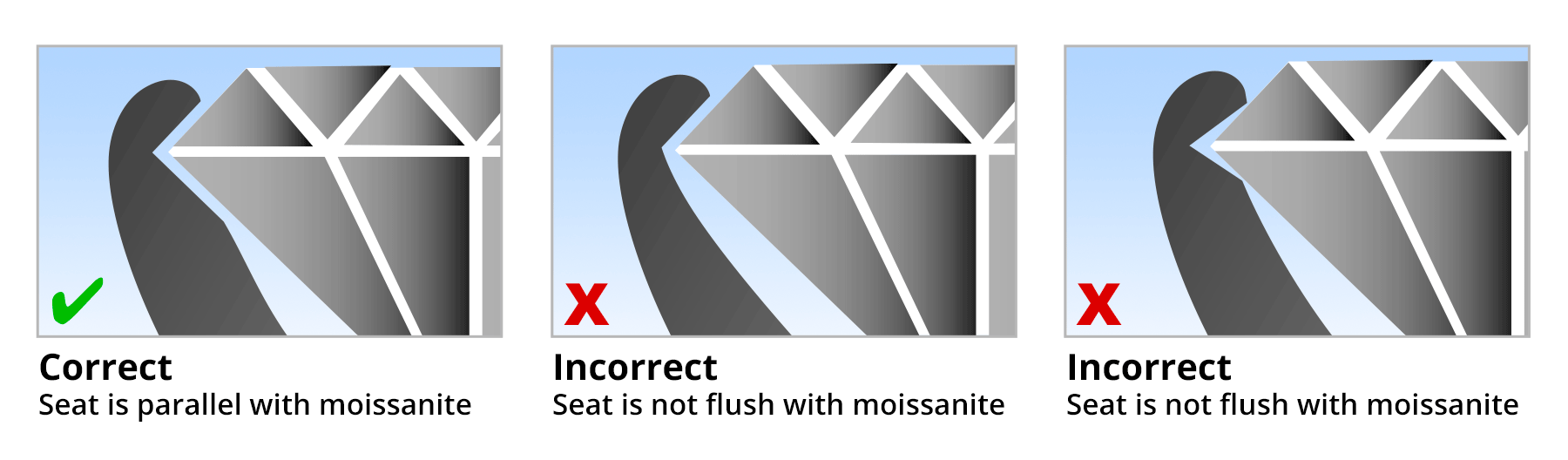

Prong Setting: If the bearings (seats) are properly made in each prong, the moissanite should pose no problem. When setting with pre-cut bearings, make sure that the lower section of the cut is parallel to the pavilion facets of the moissanite. If not, shape the lower part of the bearing so that the stone fits into it instead of being pushed up against a curved edge. In such cases, the point of contact acts as a fulcrum, and even slight pressure may chip the girdle. Look at the contact between the stone and the cut. If there is an open space next to the girdle, then the bearing’s bottom edge needs to be adjusted.

Hammer Work: If the bearings are properly cut, an electric hammer may be used to move the metal above the girdle onto the moissanite. Burnishing should be done on the metal over the stone and not against the stone.

Bezel Setting: When bezel setting these cuts, the entire bezel must be level and clear of burs. If setting a square-shaped moissanite, the corners should be drilled, and the angle at the bottom of the bearing should match the angle on the pavilion of the gem. Push downward on the metal, making sure it forms over the edge of the crown, thereby closing the bezel. Do not push the metal into the edge of the stone to close the bezel as this may cause the girdle to chip.

Bead Work: Girdles should be fitted slightly below the metal surface and beads raised above the girdle rather than against it. Girdle edges on both diamonds and moissanite may chip if direct pressure is applied against them.

Re-Tipping: A ring set with moissanite must be thoroughly cleaned and then fire-coated with a mixture a denatured alcohol and powdered boric acid. Allow the ring to air-dry before using 18KT plumb white solder with a flow temperature of around 1525°F (830°C) to re-tip the prongs. We recommend Roseco’s SDR-18KWE solder. Do not use 20kt white weld solder! If using sterling silver, only re-tip the prongs using a laser machine. Do not use silver solder of any flow type! Moissanite is sensitive to high temperatures and overheating, which can cause fracturing or burnt spots to the stone.

Polishing: No silicon carbide sanding discs, silicon carbide wheels, or drum sanders should be used around moissanite. Do not tumble polish jewelry set with moissanite as this will cause scratching of the stones. Polishing should only be done with rubber or pumice wheels. Emery paper and buff sticks are best suited for prong work. Avoid passing a rough file over the sharp facet edges or the girdle edges as this can chip the moissanite but not scratch it.

Ultrasonic and Steam Cleaning: There should be no problems cleaning a moissanite jewelry piece in a warm or cold ultrasonic tank. Be careful with cleaning a number of loose moissanite stones together in the ultrasonic because the vibration and bouncing of the stones against each other will scratch them. The use of a steam cleaner on moissanite will not harm the stone.

Acids: Moissanite may be “pickled” to remove any fire scale. The moissanite jewelry piece must be cooled to room temperature first before being placed in a pickle. Do not quench hot items! The thermal shock could break or damage the stone.

Plating: When plating moissanite jewelry, all plating solutions (e.g., rhodium, gold, etc.) must be at room temperature. Damage can occur to the moissanite if the solutions are above 90°F (32°C).

Source: Charles & Colvard