Karat Gold Solders for Jewelry

Most jewelry is composed of several components that are joined and assembled by soldering. In many countries, regulations govern the caratage of gold solders used to make jewelry and, with few exceptions, gold solder alloys should be of the same caratage as the jewelry. One problem with the production of solders is to ensure a good color match with the jewelry being assembled.

Fortunately, it is possible to make a range of carat gold solders from 8 carats up to 22 carats in the full range of colors (including white) and these are commercially available in a variety of forms.

In engineering terms, carat gold solders for jewelry are hard solders or brazing alloys, as they melt above 450°C. A requirement of solders is that their melting temperature (the liquidus temperature) is at least 20°C below the solidus temperature of the carat golds being soldered. The parent metal does not melt during soldering.

In practice, at each caratage and color, a range of solders can be designed with different melting ranges to enable ‘step’ soldering. This is to avoid the danger of remelting soldered joints made previously when doing the next soldering operation. These are normally designated ‘hard, ‘medium’ and ‘easy’ grades, with their melting ranges reducing, so that the easy grade has the lowest melting range. At low caratages an ‘extra-easy’ grade may be available, which is useful for repairing broken jewelry.

Solder Compositions

Most solders are based on the color gold-silver-copper alloys with additions of low melting point metals such as zinc, cadmium, tin and indium to lower the melting range. These additions will tend to whiten the solder alloy and so usually the copper content needs to be increased to compensate. White gold solders are based on white gold compositions with similar low melting alloying additions to lower the melting range.

Cadmium has traditionally been used in jewelry solders as it confers good melt fluidity as well as lowering the melting range. Unfortunately, it is now known that there is a serious toxicity problem with cadmium. It has a low melting point of 321°C, boils at 767°C and has a high vapour pressure. This means that, on melting the solder, it readily boils off and forms a vapour that reacts with air to form poisonous cadmium oxide fume. Exposure to this fume can cause long term health problems to workers in the jewelry industry including scrap refiners. This includes damage to lungs, kidneys and blood. Cadmium accumulates in the body and there are regulations in many countries limiting exposure to cadmium. Although good ventilation and exhaust systems should always be in place in a workshop, escape of cadmium into the atmosphere causes environmental pollution and can get into the food chain.

Cadmium has traditionally been used in jewelry solders as it confers good melt fluidity as well as lowering the melting range. Unfortunately, it is now known that there is a serious toxicity problem with cadmium. It has a low melting point of 321°C, boils at 767°C and has a high vapour pressure. This means that, on melting the solder, it readily boils off and forms a vapour that reacts with air to form poisonous cadmium oxide fume. Exposure to this fume can cause long term health problems to workers in the jewelry industry including scrap refiners. This includes damage to lungs, kidneys and blood. Cadmium accumulates in the body and there are regulations in many countries limiting exposure to cadmium. Although good ventilation and exhaust systems should always be in place in a workshop, escape of cadmium into the atmosphere causes environmental pollution and can get into the food chain.

Some governments have banned the use of cadmium in solder alloys or placed severe restrictions on its use in the workshop. Thus, many jewelers now use ‘cadmium-free’ solders. These may require a small adjustment to the soldering technique as they will ‘feel’ different. Some examples of solders are given in the following tables:

Typical Cadmium – Containing 9 ct Yellow Gold Solders

| Gold, wt. % |

Silver, wt. % |

Copper wt. % |

Zinc, wt. % |

Cadmium, wt. % |

Melting Range, °C |

|

| extra easy | 38.5 | (22)* | (19)* | (2.5)* | (18)* | 620 -690 |

| easy | 38.5 | (30) | (19) | (2.5) | (11) | 650 -720 |

| medium | 38.5 | (37) | (18) | (2) | (5.5) | 735 – 755 |

| hard | 38.5 | (29) | (28) | (5.5) | – | 755 – 795 |

* (X) indicates approximate amounts. Actual amounts are proprietary alloys. Melting range of a typical 9 ct yellow casting alloy is 880 – 900 °C. Cadmium-free 9 ct gold solders are also available.

Cadmium – Free 10 & 14 ct Gold Solders

| Gold, wt % |

Silver wt % |

Copper wt % |

Zinc wt % |

Tin wt % |

Indium wt % |

Melting Range °C | |

| 10ct easy | 41.67 | 27.10 | 20.90 | 5.33 | 2.50 | 2.50 | 680 – 730 |

| 10ct medium | 41.67 | 29.40 | 22.18 | 4.25 | 2.50 | – | 743 – 763 |

| 10ct hard | 41.67 | 33.25 | 23.85 | 1.23 | – | – | 777 – 795 |

| 14ct easy | 58.33 | 14.42 | 13.0 | 11.75 | – | 2.50 | 685 – 728 |

| 14ct medium | 58.33 | 17.50 | 15.67 | 6.0 | 2.50 | – | 757 – 774 |

| 14ct hard | 58.33 | 20.0 | 18.17 | 3.50 | – | – | 795 – 807 |

Melting range of typical 10 ct casting alloy is 830 – 895 °C.

18ct Gold Solder Alloys: Cadmium-Containing and Cadmium-Free

| Gold, wt % |

Silver, wt % |

Copper wt % |

Zinc, wt % |

Tin, wt % |

Indium wt % |

Cadmium wt % |

Melting range, °C |

|

| ‘easy’ | 75.0 | 5.0 | 9.3 | 6.7 | – | 4.0 | – | 726-750 |

| ‘medium’ | 75.0 | 6.0 | 10.0 | 7.0 | – | 2.0 | – | 765-781 |

| ‘hard’ | 75.0 | 6.0 | 11.0 | 8.0 | – | – | – | 797-804 |

| ‘medium’ | 75.0 | 2.8 | 11.2 | 9.0 | – | – | 2.0 | 747-788 |

| ‘hard’ | 75.0 | – | 15.0 | 1.8 | – | – | 8.2 | 793-822 |

Melting range of typical 18 ct yellow alloy: 855-875°C.

21 Carat Solder Compositions – Cadmium-free

| Gold, wt % |

Silver, wt % |

Copper wt % |

Zinc, wt % |

Indium, wt % |

Tin, wt % |

Gallium wt % |

Melting range, °C |

|

| No 3 | 87.5 | 4.0 | 3.5 | 5.0 | – | – | – | 834-897 |

| No 4 | 87.5 | – | 5.5 | 4.8 | 2.2 | – | – | 751-840 |

| No 7 | 87.5 | – | 8.5 | – | 4.0 | – | – | 786-894 |

| No 12 | 87.5 | 2.0 | 3.0 | 7.5 | – | – | – | 785-837 |

| No 13 | 87.5 | 1.5 | 6.0 | 5.0 | – | – | – | 840-884 |

| No 17 | 87.5 | – | 5.5 | 5.0 | – | – | 2.0 | 677-813 |

Melting range of typical 21 ct yellow gold: 941-960 °C. Solder alloy data taken from paper by D.Ott, Gold Technology, No 19, July 1996. Gold Technology, No 19, July 1996

22 Carat Solder Compositions – Cadmium-free

| Gold % |

Silver % |

Copper % |

Zinc % |

Indium % |

Melting range °C |

| 91.6 | 0.4 | 3.0 | 5.0 | – | 865 -880 |

| 91.6 | – | 3.0 | 4.4 | 1.0 | ? low* |

| 91.6 | – | 3.0 | 3.4 | 2.0 | ? low* |

| 91.6 | – | – | 8.4 | – | 754 – 796 |

| 91.6 | 1.0 | – | 7.4 | – | (a little higher) |

| 91.8 | 2.4 | 2.0 | 1.0 | 2.8 | 850 – 895+ |

| 91.8 | 3.0 | 2.6 | 1.0 | 1.6 | 900 – 895?+ |

| 91.8 | 4.2 | 3.0 | 1.0 | – | 940 – 960+ |

Melting range of typical yellow 22 ct gold: 995-1020°C. *- Adapted from 21 ct solder compositions – melting range not yet measured. +- From Indian Standards IS 3095: 1999.

To vary the color of colored solders to achieve a color match, the compositions should be adjusted. To make a solder more red, increase copper and reduce silver. To make a paler yellow, reduce copper and increase silver (and/or zinc). Remember, that such changes will alter the melting range.

There is a 22 ct yellow gold solder with a very low melting point. This has the composition 92.5 % gold – 6.0% germanium -1.5% silicon and is based on the ternary eutectic system. The soldering temperature is 425-450°C and although the joints are initially whitish in color they can be heat treated for 2 hours at 285°C to give a good color match to yellow gold. It is not possible to solder in air using a gas torch and flux but the process is suitable for soldering in a furnace with an inert or reducing gas atmosphere. Mechanically strong ductile joints of excellent quality can be made. The work is reported in Gold Bulletin, 29, (1), 1996.

The following table illustrates some white gold solders, based on nickel white gold compositions. Nickel-free compositions to meet European Directive requirements on Nickel are based on low palladium (palladium increases melting range) and other whitening agents such as manganese with low melting point additions such as zinc and indium.

White Gold Solders, Cadmium-free

| Grade | Gold % |

Silver % |

Copper % |

Nickel % |

Zinc % |

Melting Range, °C |

| 10 ct Easy | 41.67 | 28.1 | 14.1 | 10.0 | 6.13 | 763-784 |

| 10 ct Hard | 41.67 | 30.13 | 15.1 | 12.0 | 1.1 | 800-832 |

| 14 ct Easy | 58.33 | 15.75 | 5.0 | 5.0 | 15.9 | 707-729 |

| 14 ct Hard | 58.33 | 15.75 | 11.0 | 5.0 | 9.92 | 800-833 |

| 18 ct Easy | 75.0 | – | 6.5 | 12.0 | 6.5 | 803-834 |

| 18 ct Hard | 75.0 | – | 1.0 | 16.5 | 7.5 | 888-902 |

Melting ranges of typical nickel white gold: 10 ct casting alloy: 970 -1017°C; 14ct casting alloy: 940 – 977°C; 18 ct casting alloy: 915-948°C.

Forms of Solder

Typically, goldsmiths use solder in the form of wire, thin strip or coupons (‘Paillons’) cut from strip. However, there is a growing use of solder in the form of solderpaste.

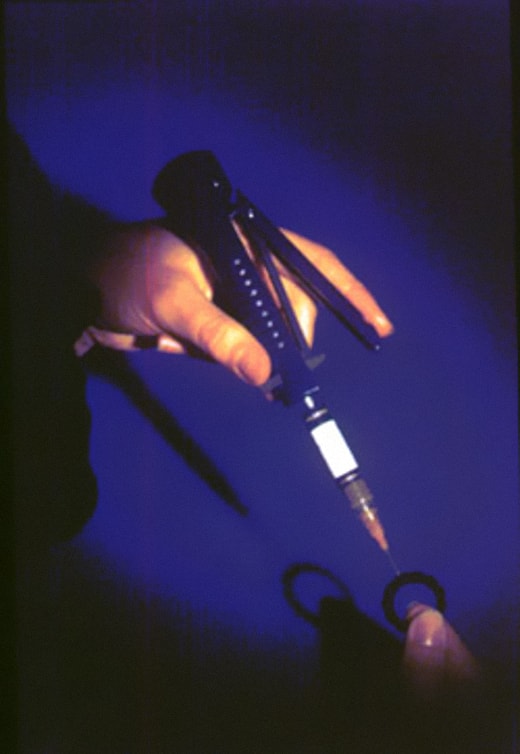

Solder pastes are homogenised mixtures of solder in the form of a very fine carat gold alloy powder combined with an organic binder which may or may not contain a flux depending on whether torch heating or furnace heating with a protective atmosphere is to be used. The paste is dispensed from plastic syringes using a hollow needle of appropriate size. An electro-pneumatic device is used to supply compressed air for a pre-determined time interval to deliver an exact and reproducible amount of paste to the joint. Where precise control is not required, simpler hand operated syringes can be supplied. The solder paste can be supplied in all caratages and colors up to and including 22 ct. They do cost more than the conventional wire and strip forms but there are considerable benefits, some of which are cost saving. These are:

- a saving in time

- an exact control on the amount of solder to be used

- less wastage of expensive solder alloy

- reduced reject rate or complete elimination of poorly formed joints

- more precise positioning of solder compared with using paillons

- increased production rates and possibility of semi-automation

- unskilled personnel can be easily trained to use the dispensers.

Hand dispensing of solderpaste (Courtesy of H.Hildebrand et Cie, Switzerland). The pastes, which are supplied in their dispensers, have a long shelf life even when partially used. (Reference: H Hilderbrand, “Gold Solder Pastes”, Gold Technology, No.9, May 1993).

Other forms of solder in use are:

- Solder flush strip or sheet. Here a thin layer of carat gold solder is bonded to the sheet of carat gold used for stamping parts of jewelry. The solder is located on the internal surface and when the 2 halves of the stamping are mated together, they can be passed through a belt furnace, where the solder melts and joins the 2 halves. The major disadvantage is that scrap strip after stamping cannot be simply remelted and recycled as its composition and properties will be changed.

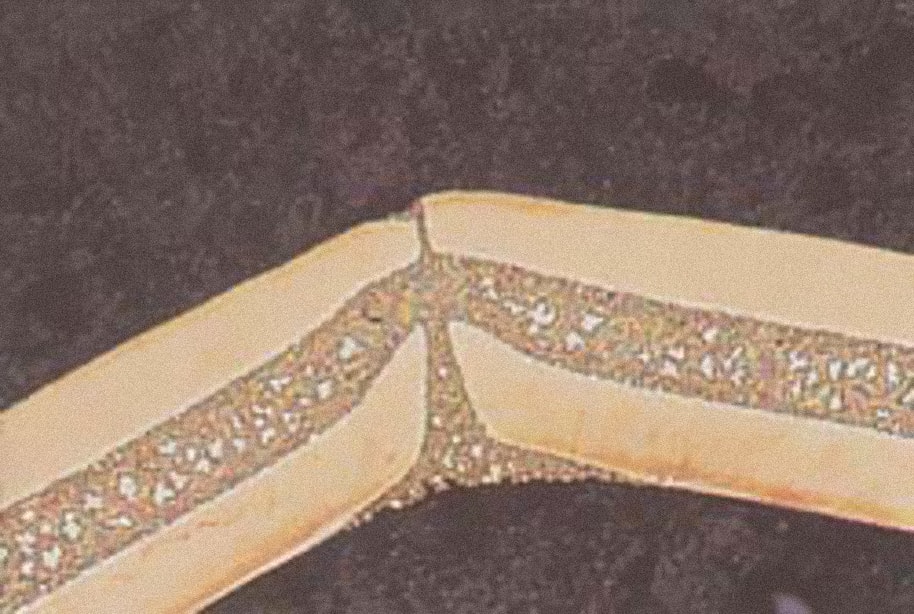

- Solder-cored wire for chain making: The wire for chain making contains a central core of carat gold solder and is used for making the chain on a chain machine in the usual way. It can then be passed through a belt furnace for soldering. The central core of solder melts and gives clean soldered links.

Section of soldered carat gold chain link made with solder-cored wire

Source: World Gold Council